- Place of Origin:

-

Guangdong, China (Mainland)

- Brand Name:

-

AN HU SHEN

- Model Number:

-

EJH-28

- Electrical source:

-

AC110V/220V/380V 50/6 0Hz.

- Power:

-

120w

- SupplyAbility:

- 50 Piece/Pieces per Month

- Packaging Details

- 174*90*103cm

- Port

- SHENZHEN

- Lead Time :

- Shipped in 15 days after payment

//

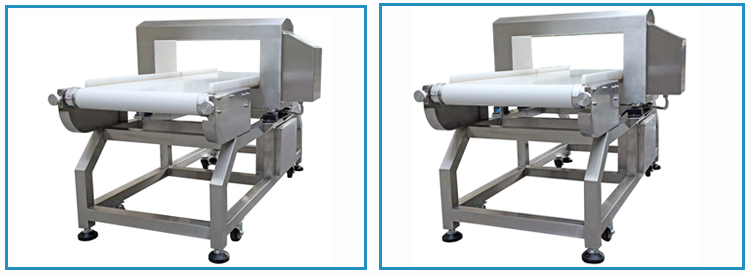

Industrial metal detector

Advanced technique of electrical & mechanism designs is adopted for EJH series auto-conveying metal detector which have reasonable structure, beautiful appearance, highly detection sensitivity and stable behaviors. It is characterized by high detecting sensitivity and stable & reliable performance.

Product characteristic

The electronic and mechanism design of the series of EJH auto-conveying metal detector is adopted advanced technique in the world, the design is suitable and the appearance is beautiful EJH-14 owns the ability of high sensitivity and stable behavior

Scope of application:

EJH-28 is mainly used for detecting the metal chips inside the sea-food , fishery, noodle, frozen food, sugar, tea, pharmaceutical products etc.

Product characteristic :

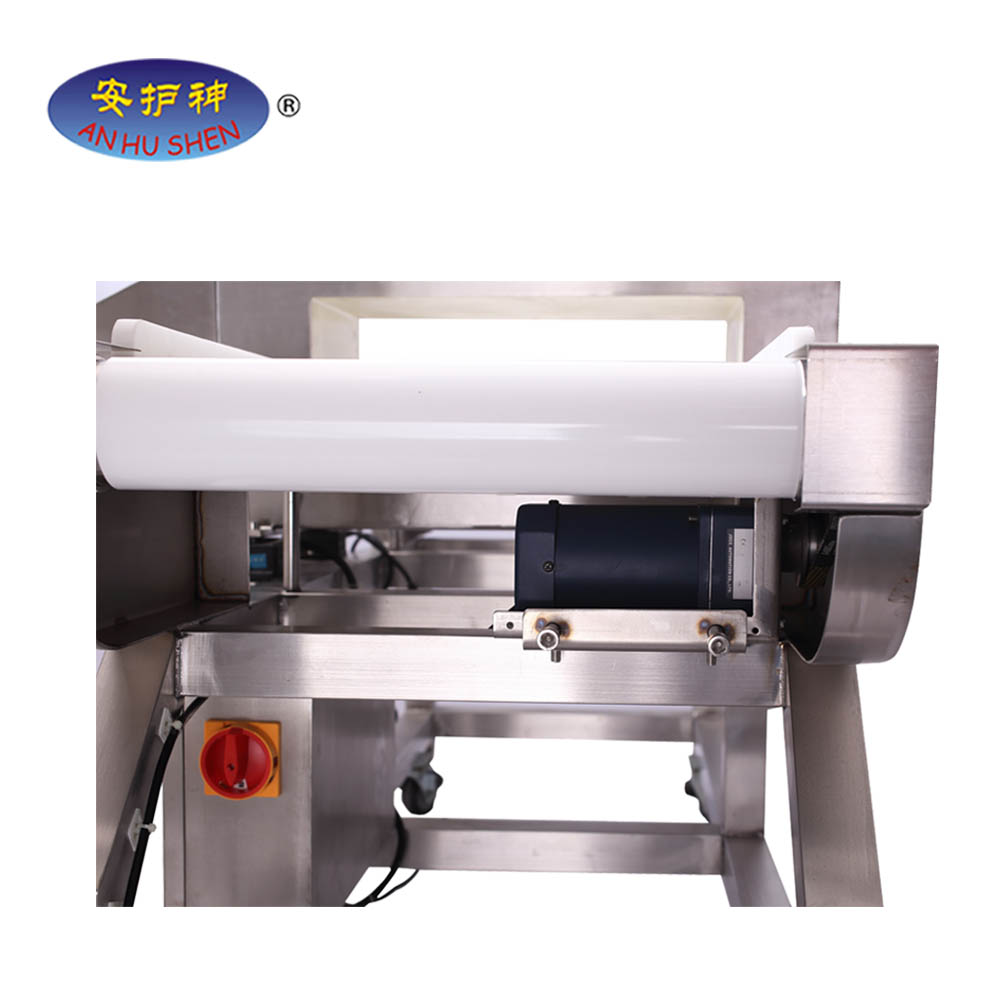

1: Stainless steel shell , anti-erosion and long life span .

2: The conveyor belt is made of nonpoisonous material

3: Strong transport drive, all the products below 25kg can be conveyed to be checked.

4;Quick convey speed, it is specially suitable for pipeline operation.

5: When sensor detect a broken needle or over a diameter 0.8mm iron ball, buzzer will sound and conveyor belt will stop. After that, detected products will be return at hand.

6. Water-Proof, IP66 compliant

7:The performance of the belt conveyer is complied with the American food sanitation standard (FDA), it can be used for transporting the unpacked food directly.

8: Can match the pipeline operation or automatic control device.

Features: LCD display, DSP digital signal processing technology, OSD menu in Chinese and English.

Recording and memory function: able to store up to 20 kinds of different products.

Dual- channel and dual-frequency detecting to detect Fe and non-ferrous metals like stainless steel respectively.

360 degree phase indentifying technology adopted to decrease product effect and improve sensitivity in non-ferrous metal detecting.

With high stability: no alarm even if being hammered.

The Food industry conveys belt confirms to FDA standard and can be used to convey unpacked food directly.

Can be integrated into production line or automatic equipment.

Way of alarming: sound and light alarm, stop running automatically.

-

Manufactur standard Portable Hand-held Metal De...

-

Factory wholesale Thermometer For Room Temperat...

-

8 Year Exporter auto-conveyor metal detector - ...

-

High Quality for X Ray Gold Testing Analyzer - ...

-

Hot-selling Quick Weight Loss - Super Scanner ...

-

Wholesale Digit Auto Checkweigher Scale - Dept...