- Place of Origin:

-

Guangdong, China (Mainland)

- Brand Name:

-

AN HU SHEN

- Model Number:

-

EJH-D330

- stainless steel:

-

silver grey

- Power:

-

120w

- Electrical source:

-

AC110V/220V/380V 50/6 0Hz

- 500 Piece/Pieces per Month

- Packaging Details

- 174*90*103cm

- Port

- SHENZHEN

- Lead Time :

- within 10-15 working days after getting the payment

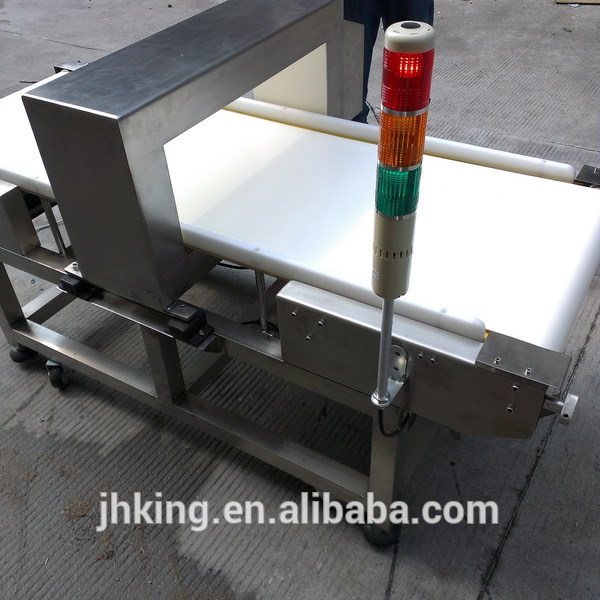

The electronic and mechanism design of the series of EJH auto-conveying metal detector is adopted advanced technique in the world, the design is suitable and the appearance is beautiful,

EJH-330 owns the ability of high sensitivity and stable behavior.

Scope of application

EJH-330 is mainly used for detecting the metal chips inside the sea-food, fishery, noodle, frozen food, , sugar, tea, pharmaceutical , food additive, condiment, health care products etc.

Product characteristic

1. all made of Stainless steel , anti-erosion and long life span.

2. The conveyor belt is made of nonpoisonous material

3. Strong transport drive, all the products below 25kg can be conveyed to be checked.

4. Water-Proof, IP66 compliant

5. Good Anti-interference function: reduce product effect signal form the frozen food and pickled food.

6. The performance of the belt conveyer is complied with the American food sanitation standard (FDA), it can be used for transporting the unpacked food directly.

7. Can match the pipeline operation or automatic control device.

Technical parameters:

1. Inspection window size:

Normal height of inspection window (mm): 200

Normal width of inspection window (mm): 500

The measures of the inspection window can be designed according customers requirement.

2. Sensitivity: Diameter of 0.8 mm steel ball, weight of 1.2-1.5g Lead, copper and other globular metal at normal window

3: Electrical source: AC110V/220V/380V 50/6 0Hz.

4: Power: 120W

5: Alarm: Audible and visual alarm, automatic stop

6: Normal Size (mm): 1740(L) X 900(W) X1030(H)

7: Gross Weight: approx 350Kgs Net Weight: Around 3000kgs

Can be installed with the auto-rejection equipment according customer’s requirement.

Note: The above sensitivity judged by the machine without carrying any products, the actual detection sensitivity has relation with the nature and the temperature of the products etc., The sensitivity would be affected by the type of the products and the working condition.

-

Factory wholesale Cheap Gold Detector - Multi-...

-

High reputation Metal Detector Wands - Baggage...

-

Best quality Check Weigher With Rejection Syste...

-

Reasonable price Food X-Ray Inspection Machine ...

-

18 Years Factory Gc1001 Body Scanner - Automat...

-

Big Discount Under Vehicle Camera - Portable A...