- Place of Origin:

-

Guangdong, China (Mainland)

- Brand Name:

-

AN HU SHEN

- Model Number:

-

EJH-14

- Material:

-

Stainless steel

- color:

-

silver

- Product name:

-

Food Metal Detector

- Sensitivity:

-

High sensitivity

- Warranty:

-

1 Year(labor and parts)

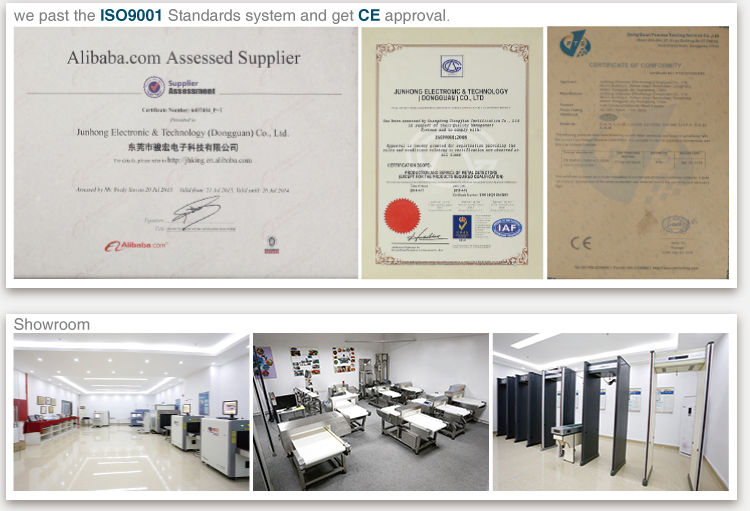

- Certificates:

-

CE. ISO

- Power supply:

-

120W 12V

- Type:

-

Conveyor metal detector

- Usage:

-

food,plastic,rubber,wood,textile

- Inspection:

-

ferrous,non ferrous,stainless steel

- SupplyAbility:

- 20 Piece/Pieces per Month

- Packaging Details

- 174*90*103cm

- Port

- SHENZHEN

- Lead Time :

- within 15-20 working days after getting the payment

//

2017 factor direct supply albania metal detector for promotion

Features:

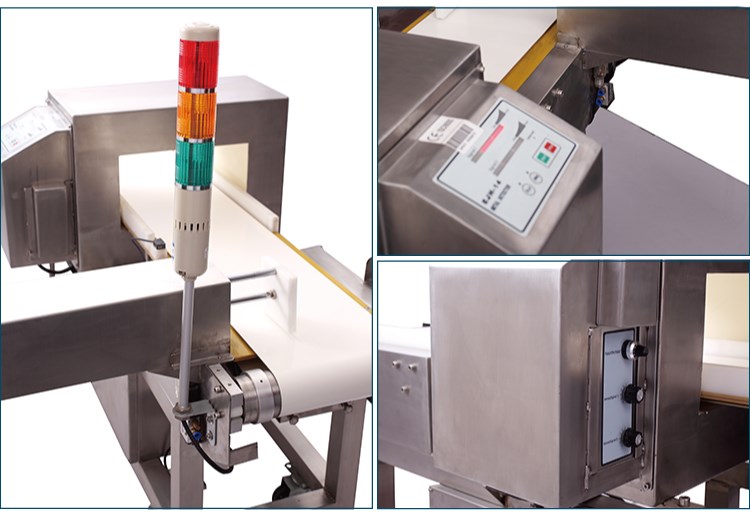

The electronic and mechanism design of the series of EJH auto-conveying metal detector is adopted advanced technique in the world, the design is suitable and the appearance is beautiful ,EJH-14 owns the ability of high sensitivity and stable behavior.

Scope of application

EJH-14 is mainly used for detecting the metal chips inside the sea-food , fishery, noodle, frozen food, , sugar, tea, pharmaceutical products etc.

Product characteristic

1. Stainless steel shell , anti-erosion and long life span .

2. The conveyor belt is made of nonpoisonous material

3. Strong transport drive, all the products below 25kg can be conveyed to be checked.

4. Quick convey speed, it is specially suitable for pipeline operation.

5. When sensor detect metal part, buzzer will sound and conveyor belt will stop.

6. The performance of the belt conveyer is complied with the American food sanitation standard (FDA), it can be used for transporting the unpacked food directly.

7. Can match the pipeline operation or automatic control device.

8 .conveyor belt speed 15 meter/minute to 35 meter /minute.

Technical parameters

1. Inspection window size:

Normal height of inspection window(mm): 15

Normal width of inspection window(mm): 400

The measures of the inspection window which can be designed according customers requirement.

Electrical source: 220V 50Hz

Power : 120W

2. Sensitivity: ferrous 1.5mm .non-ferrous 4.0mm,stainless steel 3.5mm

Table of Sensitivity

|

|

25*8cm | 30*10cm | 40*15cm | 50*20cm | 50*40cm | 60*30cm |

|

FE |

≥0.5mm | ≥0.8mm | ≥0.8mm | ≥1.0mm | ≥2.0mm | ≥1.5mm |

|

SUS |

≥1.2mm | ≥1.5mm | ≥2.0mm | ≥2.0mm | ≥4.0mm | ≥3.0mm |

Remark: the above data is empty machine sensitivity. The real sensitivity will be lower on condition of different products being tested.

Quality assurance:

One year limited warranty(Labor and parts)

PACKAGE:

Standard export carton packing.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Textile and Apparel Industry Needle detector EJH-2

metal detector food processing industry

Industry conveyor belt metal detector for meat food

X-Ray screening system for food industry

-

2017 Latest Design Portable Dental Unit - Meta...

-

Factory directly Car Mirror Protector - Remote...

-

Manufacturer of x-ray parcel scanning machine ...

-

OEM Customized Bomb Detector - Teenagers Under...

-

Reliable Supplier Printed Circuit Board For Sta...

-

Factory made hot-sale Deep Earth Gold Finder - ...