- Place of Origin:

-

Guangdong, China (Mainland)

- Brand Name:

-

Anhushen

- Model Number:

-

EJH-D300

- Certification:

-

HACCP,QS,ISO9001,CE

- Material:

-

Stainless stell

- Founction:

-

Metal detector machine

- Technology:

-

Digital,DSP,DDS

- Total records:

-

15 Kinds of different product

- Operation menu:

-

Easy operation

- Style:

-

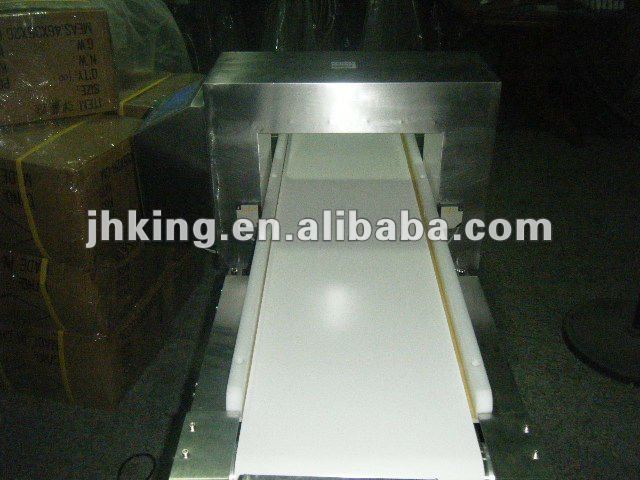

Conveyor belt style

- Speed of transmission:

-

18-40Meters

- Main power:

-

200w/400w

- Language:

-

English/Chinese

- SupplyAbility:

- 200 Set/Sets per Month

- Packaging Details

- export wooden case

- Port

- Shenzhen

- Lead Time :

- 15 working days

{“detailModule.supplyAbility.tip”:”If you finish the payment today, your order will ship out within the delivery date.”,”detailModule.supplyAbility.title”:”SupplyAbility”}

Digital conveyor belt food metal detector used for production line

Mainly used for detecting various needle breakage, steel wire, lead, copper, stainless steel and other colored metals that load or drop in raw materials and products in the field of toy, costume, shoemaking, chemical industry, leather, knittingetc.

Introduction:

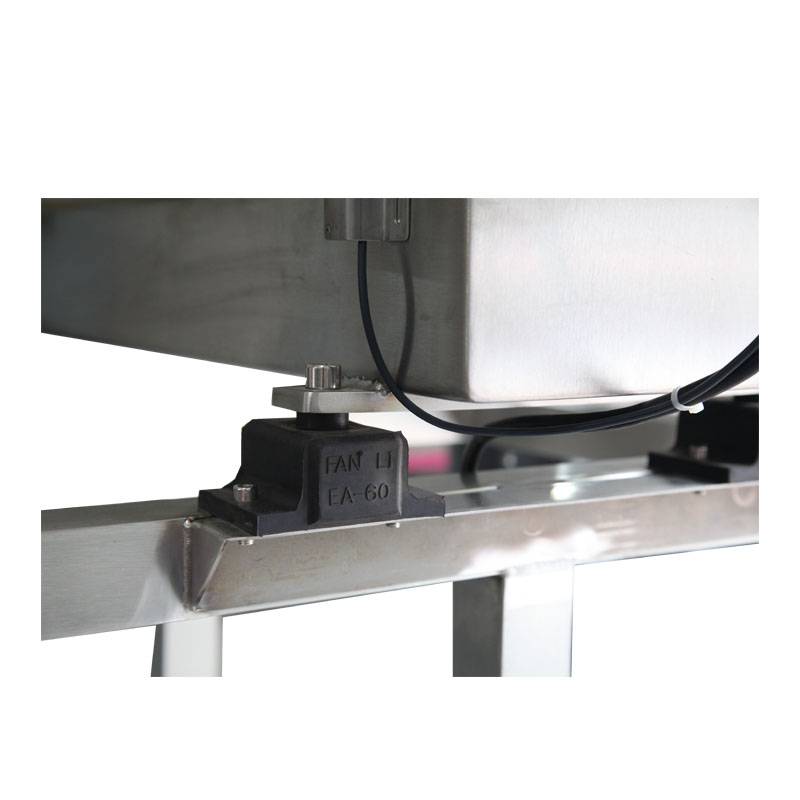

EJH-D300 Series digital style of intelligent metal detectors, using kinds of the most advanced electronics, Adopt electromagnetic detection and DSP,DDS and many other digital signal processing technology.

Comparing with traditional simulation detector , the function is more completely , the capability is more stable and dependable. Its specifically for food, medicine, chemicals, rubber and metal needs detection of application-specific design occasions. Particularly suited to tobaccos, toys, footgear, cosmetics, lavation products, plastics, leathers, building material and other industries. It accord with the demand of certification-HACCP, QS, ISO9000.

Feature:

1. Simple operation menu, all settings and using are simple and convenient without any adjustment for operators.

2. all the equipment parameters of detection are locked automatically, when use it, you can just place the product that needs detected on the conveyors, then the system of detection will recognize automatically.

3. It can detect the iron, stainless steel, copper, Al and all kind of metal chips which mixed with products. as well as, some of non-metal that transmitting electricity and magnetism.

4. can record up to 15 kinds of different products, parameters of detection and the most simple operation is replacement of different products occasions frequently.

5. The style of conveyors is opening and unloading structure, for day-to-day cleaning.

Widely using scope

1. Apply to food (including aquatic products and quick-frozen food, extruded food, etc..) pharmaceuticals, plastic, chemicals textiles and other occasion that need metal detection.

2. Apply to high temperature, low temperature(minus twenty degrees), damp, dry, dust, dew and other poor work environment.

High sensitivity detection :

1. using the detection circuit with specially high-performance design and with advanced digital signal processing algorithms. The actual detection proved that it reached the most advanced international level.

2. against the variety of detector products , with the learning functions of automatic identification. Overcome the effect of products material efficiently.

3. detection probe is designed specially and improved the detection sensitivity further. Improve the detection sensitivity.

good stability

1. Adopting DSP, DDS and many other digital technology to process testing signal. Comparing with traditional simulation detector , it has the advantage of universal function, stable capability, high credibility.

2. Timber known, fine craft, solid structure, good-looking in appearance, durability.

3.main structure adopted international SUS304 manufacturing, the sandblasted surface treatment, good corrosion resistance, good-looking and easy to clean.

PERFORMANCE:

Detection style: digital intelligent with LCD display

Language : chinse, English,

Motore power: 200w/400w

The main material: SUS 304

Specification parameter:

|

Dimension of window: |

25cm×8cm |

30cm×10cm |

40cm×15cm |

50cm×20cm |

60cm×30cm |

|

Sensitivity Fe: |

≥0.5mm |

≥0.6mm |

≥0.7mm |

≥1.0mm |

≥1.2mm |

|

SUS304 |

≥1.0mm |

≥1.2mm |

≥1.5mm |

≥2.0mm |

≥2.3mm |

Speed of transmission: 18-40 meter/minute

Normal height of inspection windowcm:10

Normal width of inspection windowcm:50

Alarm: Audible and visual with automatic stop

Can install with the auto-rejection equipment according customers requirement.

Power: AC110V/220V/380V 50/6 0Hz.

Note: The above sensitivity judged by the machine without bearing any parts, the actual detection sensitivity has relation with the nature and the temperature of the products etc., the different types of detection which the sensitivity of metal detectors is different too, the actual detection sensitivity should be at the base of the test-block verification.

-

High Performance Diamond Metal Detector - Over...

-

New Arrival China Hospital Portable 100ma X Ray...

-

OEM Supply x-ray parcel scanning machine - Ver...

-

Reliable Supplier Keychain Key Finder - Advanc...

-

Fixed Competitive Price x-ray parcel scanning m...

-

Trending Products Hot Selling Alcohol Tester - ...