- Place of Origin:

-

Guangdong, China (Mainland)

- Brand Name:

-

Anhushen

- Model Number:

-

EJH-14

- Usage:

-

detected the metal inside products

- Conveyor belt:

-

PVC/PU

- Material:

-

304 Stainless Steel

- Tunnel size:

-

can be customized per requirements

- SupplyAbility:

- 50 Piece/Pieces per Month

- Packaging Details

- Strong Wooden case

- Port

- shenzhen

- Lead Time :

-

Quantity(Sets) 1 – 1 2 – 2 >2 Est. Time(day) 15 18 To be negotiated

welcome to>>Junhong Electronic & Technology (Dongguan) Co., Ltd.

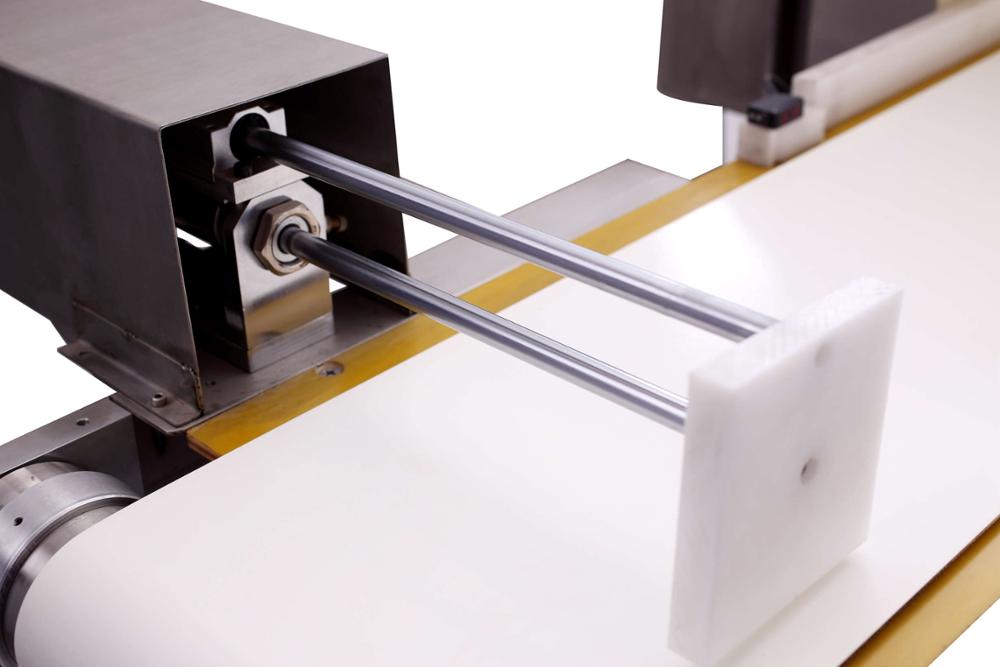

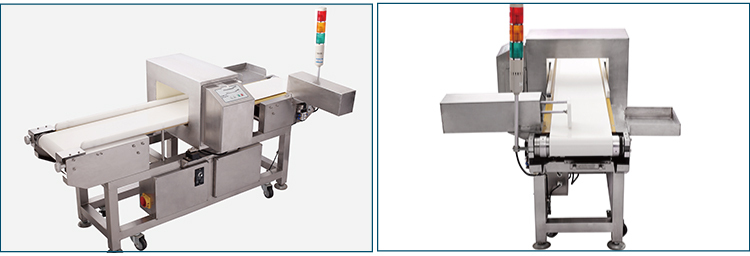

Product Photos

Types of Contaminants

There are three main groups of metallic contaminants that a food metal detector can sense:

Ferrous

Non Ferrous

Stainless Steel detection depends on the magnetic or conductive properties of the contaminant

The ability for a conventional metal detector used in the food industry to detect metallic contaminants depends upon their conductivity and magnetic permeability:

Ferrous metal contaminants are both magnetic and conductive and are easily detected.

Although they are not magnetic, Non-Ferrous contaminants are good conductors and can be detected relatively easily.

Stainless Steel foreign bodies are the most difficult to pick-up as they are usually non-magnetic and a poor electrical conductor. The ability to detect stainless steel is also hindered when the product is wet or has a high salt content.

Features:

l Dual channels dual frequencies type detector.

l Sensitivity& Product Effects could be adjustable in manual.

l IP65 dust and water proof.

l The performance of the conveyor belt is complied with the American food sanitation standard (FDA), it can be used for inspection of the unpacked food directly.

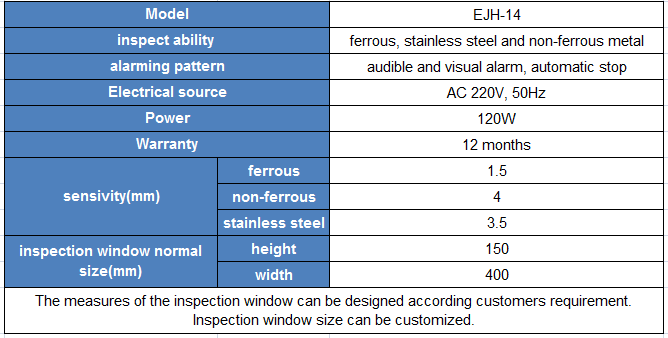

Specifications:

Material: 304 type stainless steel for detector, 201 type stainless steel for frame, PVC/ PU white belt.

Belt length (mm): 1600mm.

Conveyor height from belt to ground 650mm + 100mm feet adjuatable, with wheels moveable.

Alarm: buzzer / warning lights.

Rejection system:

l Stop on Detect Reject(50KG) – The conveyor system stops if metal is detected and an alarm sounds, enabling the operator to remove the contaminated product.

l Pusher Reject(10KG) – Pneumatically powered pushers divert contaminated product out of the production flow/ belt.

l Flap Reject – End Flap/Lift Flap reject mechanism are typically used to remove contaminated and/or out of spec dry bulk products. Product passes through a chute which in the open position allows good product to continue through. The end flap or lift flap is triggered to divert contaminated or out of spec product out of the good product flow.

Flow speed: 25 m/ min fixed or 10 to 40 m / min variable.

Flow direction: from left to right or opposite(facing control panel).

Language for operation system: English/Chinese.

Electronic source: AC110V/220V, 50/60Hz, power: 90/120/200W.

Technical parameters

Table of Sensitivity

|

|

25*8cm |

30*10cm |

40*15cm |

50*20cm |

50*40cm |

60*30cm |

|

FE |

≥0.5mm |

≥0.8mm |

≥0.8mm |

≥1.0mm |

≥2.0mm |

≥1.5mm |

|

SUS |

≥1.2mm |

≥1.5mm |

≥2.0mm |

≥2.0mm |

≥4.0mm |

≥3.0mm |

Remark: the above data is empty machine sensitivity. The real sensitivity will be lower on condition of different products being tested.

Factory

| X-ray | Walk through metal detector | Under ground metal detector |

| Hand held and underground metal detector | Food metal detector | Others |

-

Factory directly Metal Detector Door - gold fi...

-

OEM manufacturer x-ray parcel scanning machine ...

-

Cheap PriceList for Table Needle Detector For A...

-

18 Years Factory Approved Breathalyser - Airpo...

-

New Arrival China Cnc Router 4 Axis - industri...

-

Top Quality Digital X Ray Machine For Sale - P...