- Place of Origin:

-

Guangdong, China (Mainland)

- Brand Name:

-

AN HU SHEN

- Model Number:

-

EJH-D330

- Material:

-

Stainless steel

- Application:

-

sea-food, fishery, noodle, frozen food, , sugar, tea, pharmaceutical

- Certification:

-

HACCP,QS,ISO9000,CE

- Type:

-

conveyor belt

- Belt standard:

-

FDA

- Rejection alarm system:

-

according to customer's requirements

- Sensitivity:

-

customized

- Warranty:

-

1 year

- 100 Set/Sets per Month

- Packaging Details

- 180*110(W)*100cm G.W:370kgs

- Port

- Shenzhen

- Lead Time :

- 5~10days

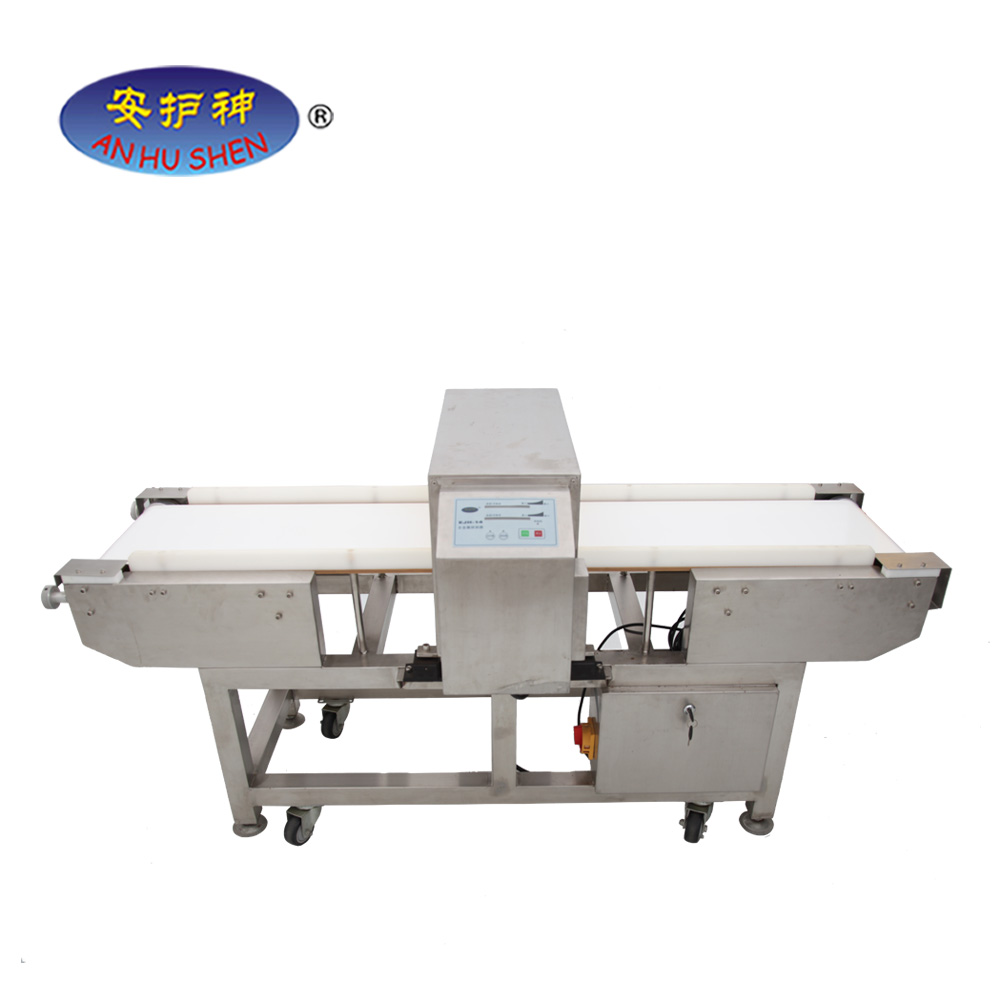

Packaging equipment metal detection for bulk foods production line

Technical parameters:

1. Inspection window size:

Normal height of inspection window (mm): 200

Normal width of inspection window (mm): 500

The measures of the inspection window can be designed according customers requirement.

2. Sensitivity: Diameter of 0.8 mm steel ball, weight of 1.2 to 1.5g Lead, copper and other globular metal at normal window size

|

Window size(WxH) |

Ferrous |

SUS304 |

|

25x8cm |

≥0.5mm |

≥1.0mm |

|

30x10cm |

≥0.6mm |

≥1.2mm |

|

40x15cm |

≥0.7mm |

≥1.5mm |

|

50x20cm |

≥1.0mm |

≥2.0mm |

|

60x30cm |

≥1.2mm |

≥2.3mm |

3: Electrical source: AC110V/220V/380V 50/6 0Hz.

4: Power: 120W

5: Alarm: Audible and visual alarm, automatic stop

6: Normal Size (mm): 1740(L) X 900(W) X1030(H)

7: Gross Weight: approx 350Kgs Net Weight: Around 300kgs

Can be installed with the auto-rejection equipment according customer’s requirement.

Scope of application

EJH-330 is mainly used for detecting the metal chips inside the sea-food, fishery, noodle, frozen food, , sugar, tea, pharmaceutical , food additive, condiment, health care products etc.

Product characteristic

1. all made of Stainless steel , anti-erosion and long life span.

2. The conveyor belt is made of nonpoisonous material

3. Strong transport drive, all the products below 25kg can be conveyed to be checked.

4. Water-Proof, IP66 compliant

5. Good Anti interference function: reduce product effect signal form the frozen food and pickled food.

6. The performance of the belt conveyer is complied with the American food sanitation standard (FDA), it can be used for transporting the unpacked food directly.

7. Can match the pipeline operation or automatic control device.

Polywood case

Guarantee:12months ( labor and parts )

accepted OEM,ODM.

Our company JUNHONG TECHNOLOGY specialized in security products and metal detectors have 10 years,

1-Trade terms:accepted FOB Shenzhen,CFR,CIF,EX Works

2-Payment method:T/T,West Union,PayPal.

-

OEM manufacturer Factory Door Frame Metal Detec...

-

Special Price for auto-conveyor metal detector ...

-

2017 Latest Design Checkweigher System - Super...

-

High definition Manual Panoramic Dental X Ray M...

-

2017 New Style Inline Detector - Cost-effectiv...

-

China Gold Supplier for 3d Printer Multi Langua...